- 商店中国大陆/简体中文

中国大陆/简体中文

Double-Sided High Transparency,

Polish-Free

Polish-Free

Double-Sided High Transparency with Glossy Finish

End-to-End Smart Production

As Low as $4 per Splint

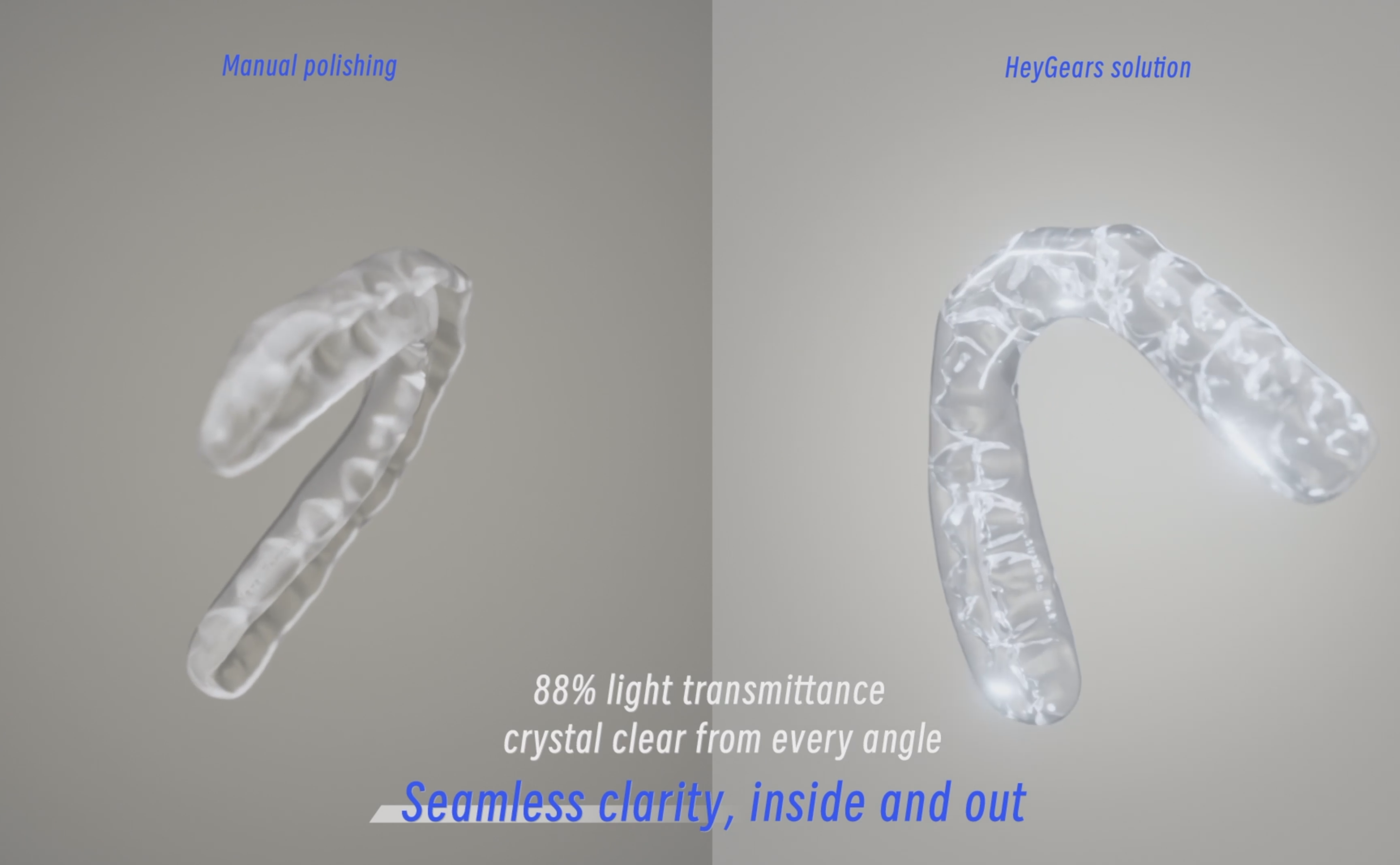

Double-Sided High Transparency

Polish-Free

Double-Sided High Transparency with Glossy Finish

Results Beyond Manual Polishing

Full-Surface 88% Light Transmittance

Crystal Clear Clarity from Every Angle, Inside and Out

*HeyGears Lab, using detax splintmaster taff & HT Resin Tank

Factory-Grade Glossy Surface

3D Printed Pre-Polished Shiny Surfaces

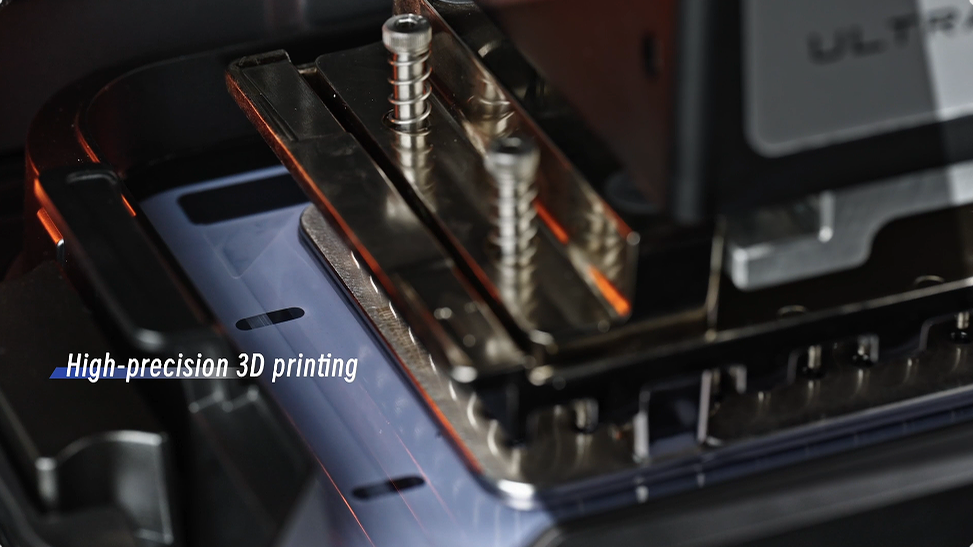

End-to-End Smart Production Minimal Manual Labor

Automated Pre-Processing & High-Precision 3D Printing

Only 45 Minutes per Unit from Pre-processing to Delivery*

*267 mins per batch/6 units

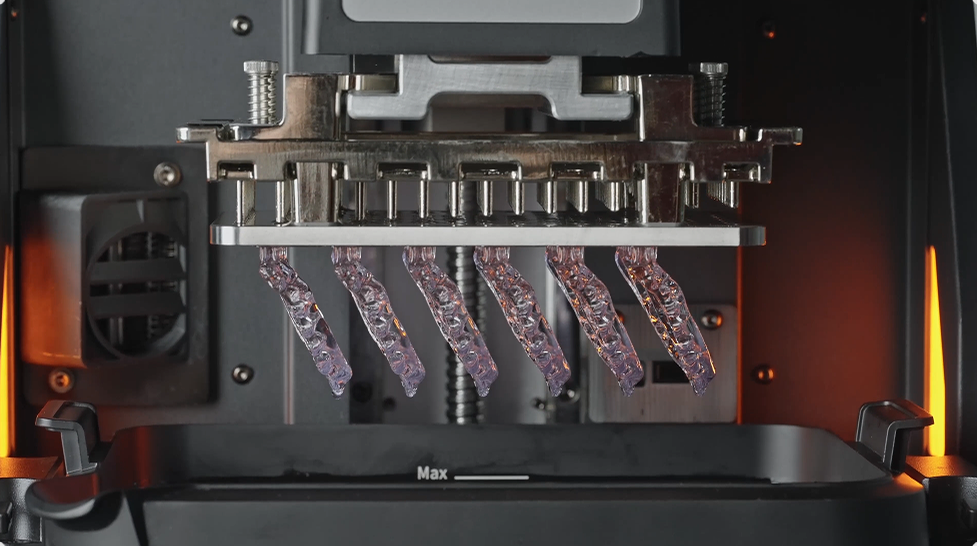

Efficient Washing + One-Click Yellowing-Free Post-Curing

Specialized Washing Fixtures Ensure Batch-to-Batch Perfection

Skip Polishing Steps

Premium Quality Splints Directly from the Printer

As Low as $4 per Splint

Enhanced Cost Efficiency

Great Value Material

Only $399

per 1 kg Bottle

High Material Utilization

101

Splints per Bottle

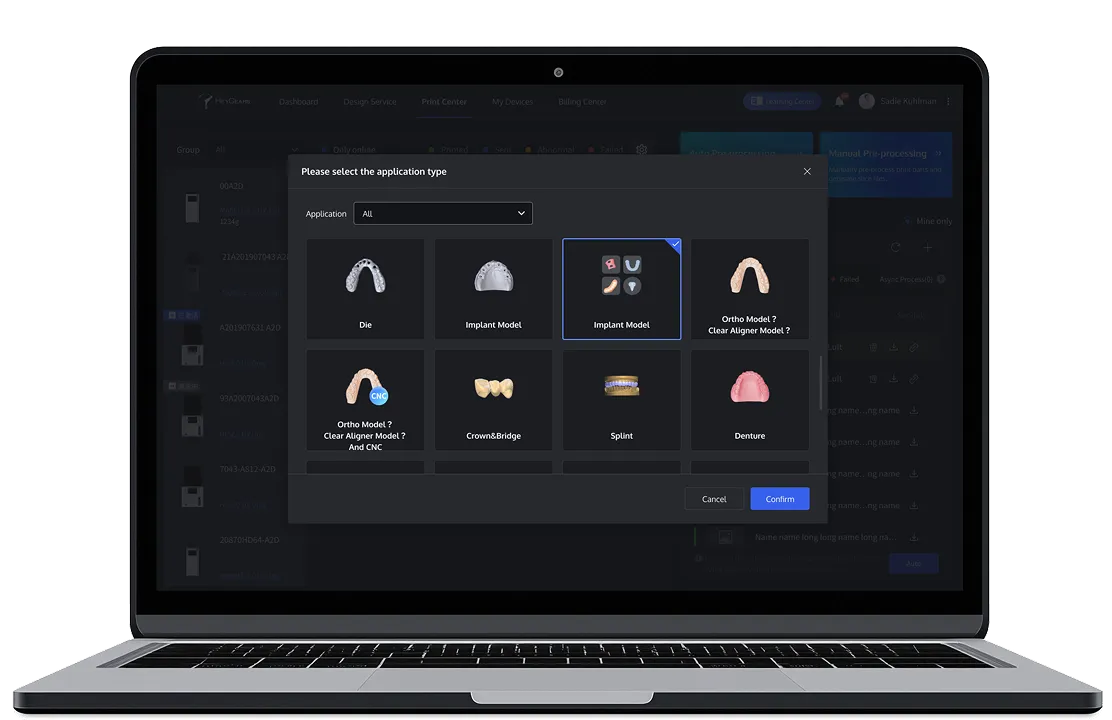

End-to-End Smart Printing Workflow for Splints

Step 1

Pre-processing (HeyGears Cloud)

· Log in and navigate to: Print → Manual Pre-processing

· Select Application → Splint → Select Printer → A2D HD → Select splintmaster taff 50 μm

· Settings: Select Layout → High transparency → Select Tank Type → HT Resin Tank

· Import file → Auto steps: Straighten → Layout → Add Supports → Slice

· Download file or drag to printer to start job

Step 2

3D Printing (UltraCraft A2D HD)

Pre-print:

Clean platform/tank, install properly

Shake resin, pour, insert resin card

Select task → Start print

Shake resin, pour, insert resin card

Select task → Start print

Post-print:

Install collection tray → Auto part-removal (avoid touching surface)

Step 3

Washing & Drying (UltraCraft Wash + Splint Wash Kit)

Solvent:

IPA (≥99%) or 95% alcohol

Steps:

Mount splint in fixture → Fill tank to mark

Wash 3 min → Replace solvent → Wash 1 min

Air-dry 10 min (no air gun)

Check residue → Rewash if needed

Wash 3 min → Replace solvent → Wash 1 min

Air-dry 10 min (no air gun)

Check residue → Rewash if needed

Step 4

Curing

UltraCraft PCU Pro:

Place on tray → Select process → Cure under inert gas

NK Optik Otoflash G171:

Place in box → 2000 flashes under inert gas→ Flip → Repeat

Note: Handle by base only

Note: Handle by base only

Step 5

Finishing

Splint Solution Workflow

Schedule a Demo